In-Mold Decorations: Changing Manufacturing Standards

In-Mold Decorations: Changing Manufacturing Standards

Blog Article

In-Mold Decorations: Elevating Products With Precision and Visual Appeals

In the realm of item layout, the marriage of accuracy and visual appeal holds a paramount position in catching customer interest and commitment. In-Mold Decorations (IMD) have actually arised as an advanced method that not just raises the aesthetic allure of products but also guarantees a careful integration of layout elements.

Benefits of In-Mold Decorations

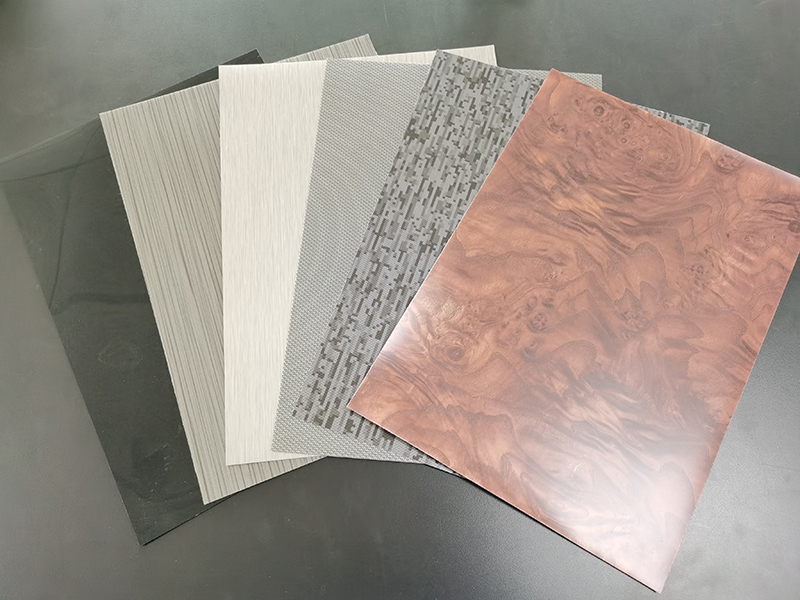

This ingenious method includes placing a pre-printed movie or tag into the mold before injecting the molten plastic, resulting in an irreversible blend of the decor with the item. The advantages of in-mold designs are manifold, beginning with the capability to accomplish high-resolution graphics and in-depth styles that boost the aesthetic allure of the last product.

Along with improving aesthetics, in-mold decorations also improve the resilience and long life of the layout as it comes to be an essential part of the item, instead of a surface layer that can disappear gradually. Furthermore, the smooth integration of decors through in-mold techniques guarantees a constant and consistent look across all made items, keeping brand consistency and quality criteria. In general, the benefits of in-mold decors make it a preferred choice for manufacturers wanting to raise their products with precision and aesthetic appeal

Precision in Style Assimilation

Achieving careful layout integration through in-mold decors requires a keen emphasis on accuracy and attention to information from the preliminary phases of the manufacturing procedure. The success of in-mold decorations pivots on the seamless assimilation of the design with the product, developing a harmonious and aesthetically attractive outcome. Accuracy in style combination entails variables such as making certain the precise positioning of the decoration within the mold, picking the appropriate materials to attain the desired aesthetic, and maintaining uniformity throughout the production process.

One trick aspect of precision in style combination is the placement of the decor with the product's contours and attributes. This needs mindful preparation and execution to make sure that the layout matches the item's form and boosts its overall appearance. In addition, interest to detail is essential in preserving the high quality and uniformity of the decorations throughout several manufacturing runs, making certain that each product meets the greatest criteria of precision and visual appeal. By prioritizing precision in design integration, manufacturers can elevate their products and create a lasting impression on consumers.

Visual Appeals and Visual Impact

With a concentrate on boosting the general charm of items, the aesthetic appeals and aesthetic effect of in-mold decorations play a pivotal duty in captivating customer attention. In today's open market, where customers are swamped with choices, the aesthetic allure of a product can be the distinguishing factor that affects acquiring choices. In-mold designs offer an one-of-a-kind chance to elevate the appearances of items by giving elaborate designs, vivid colors, and smooth coatings that traditional designing methods might struggle to accomplish.

The visual influence of in-mold designs expands beyond plain aesthetic appeals; it communicates brand name high quality, focus, and identity to detail. By including aesthetically attractive elements into item style, manufacturers can produce a solid brand name Visit This Link presence that resonates with customers on a subconscious degree. Additionally, the precision and uniformity supplied by in-mold design techniques make sure that every item meets the highest requirements of aesthetic appeal, enhancing brand name reputation and customer count on.

Cost-Effectiveness of IMD

IMD minimizes the need for secondary operations like painting or labeling, saving both time and resources. By incorporating the decor straight right into the molding procedure, IMD removes the added steps required for applying designs post-production. This structured process not only decreases labor expenses yet additionally decreases the threat of mistakes or flaws that might emerge throughout secondary enhancing procedures.

In addition, IMD enhances the longevity of decorations by encapsulating them within the product, making certain a longer-lasting and more immune coating - In-Mold Decorations. This longevity converts into minimized upkeep and substitute expenses over the product's lifecycle, making IMD an economical option for accomplishing premium aesthetics and aesthetic charm in manufacturing

Durability and Longevity

Incorporating in-mold decors not only ensures cost-effectiveness in producing processes yet additionally significantly improves item toughness and longevity. The procedure of in-mold decor involves the application of graphics or ornamental coatings during the molding procedure, creating a smooth and incorporated layout that is safeguarded within the item itself. This safety layer offered by in-mold decors works as a guard versus deterioration, scrapes, fading, and various other environmental variables that might jeopardize the look and durability of the item gradually.

Products with in-mold decorations are understood for their resistance to abrasion, chemicals, and UV exposure, making them excellent for applications that require long-term performance and aesthetic appeals. Unlike typical surface-applied decorations that can peel or fade with usage, in-mold designs come to be an intrinsic part of the item, making certain that the design stays dazzling and undamaged throughout the product's life expectancy. This sturdiness not just enhances the overall high quality of the product however additionally decreases the requirement for regular upkeep or substitutes, inevitably providing long-term cost savings for consumers and producers alike.

Final Thought

The advantages of in-mold decors are manifold, beginning with the capacity to attain high-resolution graphics and comprehensive layouts that boost the visual allure of the last item.In enhancement to improving looks, in-mold decors likewise improve the durability and long life of the style as it ends up being an important part of the product, rather than a surface layer that can put on off over time. In-mold decorations provide a distinct opportunity to boost the appearances of items by offering intricate designs, vivid shades, and seamless finishes that typical designing approaches might struggle to attain.

The process of in-mold decoration includes the application of graphics or attractive finishes throughout the molding procedure, creating a smooth and integrated style that is shielded within the item itself. Unlike conventional surface-applied decors that can peel off or discolor with usage, in-mold decorations come to be an innate part of the item, making sure that the design continues to be brilliant and undamaged throughout the item's life expectancy.

Report this page